LGB-70 screw vacuum pump

Categorize:

LGB Series

Summary:

Key words:

Vacuum equipment

LGB-70 screw vacuum pump

The pump cavity of the dry screw vacuum pump is equipped with a pair of synchronous reverse meshing rotating multi-stage spiral rotor, which divides the pump cavity into several non-connected cavities. In normal operation, with the meshing rotation of the two rotors, a suction cavity is generated and the volume increases continuously to suck in gas. When the volume reaches the maximum, the suction cavity turns into an intermediate cavity; the intermediate cavity moves to the right to transport the gas from the intake end to the exhaust end. When the intermediate cavity is connected with the exhaust port channel, the intermediate cavity turns into an exhaust cavity; the volume of the exhaust cavity decreases to discharge gas. When all the gas, the next intermediate chamber begins to be connected to the exhaust channel. This cycle to form a continuous pumping effect.

Dry screw vacuum pump can be divided into LG type equal pitch screw vacuum pump and LGB type variable pitch screw vacuum pump.

Dry screw vacuum pump is suitable for pumping all kinds of gases, and is suitable for vacuum brazing, vacuum sintering, vacuum annealing, vacuum coating, vacuum smelting, vacuum impregnation, vacuum drying, vacuum distillation, vacuum conveying, vacuum adsorption, vacuum packaging, vacuum casting and other processes. It is widely used in aerospace, electronics, metallurgy, medicine, chemical industry, semiconductor, coating, food packaging, freeze drying, casting and other industries.

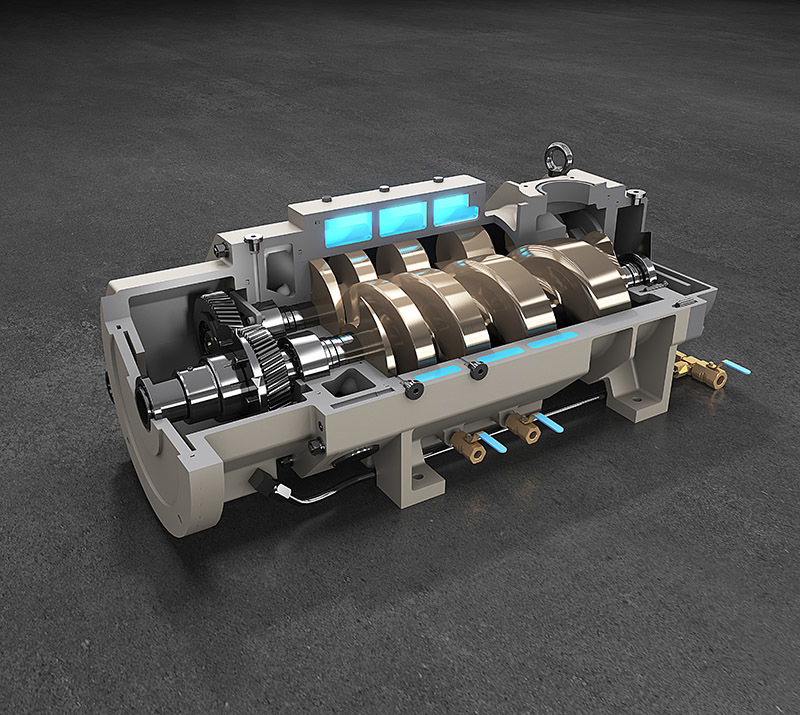

Schematic Construction Scheme:

Characteristic:

Compared with the equal pitch screw vacuum pump with the same pumping speed, the variable pitch screw vacuum pump has the following advantages:

-Lower power consumption and good energy saving effect;

-Low calorific value, low pump working temperature, low cooling water consumption;

-Low operating noise;

-Smaller size and smaller footprint.

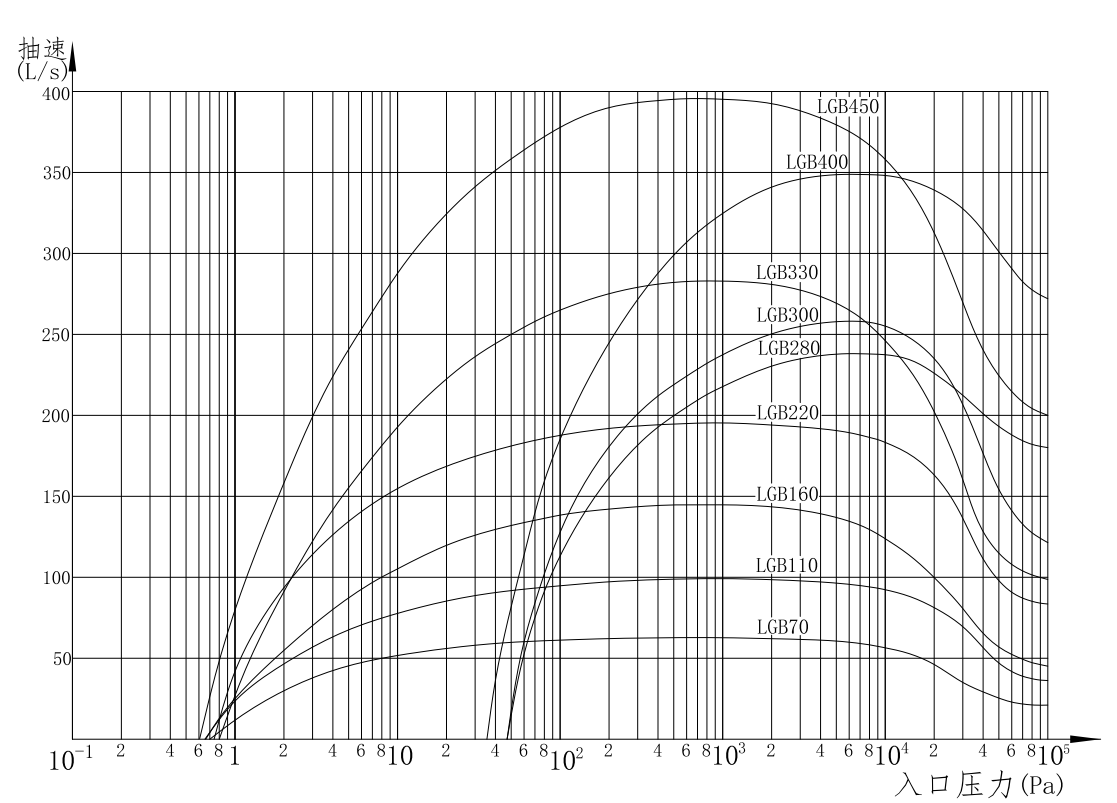

Main performance parameters Performance Parameter:

|

Model Model |

ultimate pressure Ultimate Pressure (50/60Hz) |

pumping rate Pumping Speed (50/60Hz) |

Intake caliber Inlet Diam. ( mm ) |

Exhaust caliber Outlet Diam. ( mm ) |

with power Motor Power ( kW ) (50/60Hz) |

Cooling water quantity Cooling Water Consumption ( L/min ) |

Quality Weight (kg) |

||

|

Torr |

Pa |

m3/Hr |

L/S |

||||||

|

LGB70 |

0.015/ 0.0075 |

2/1 |

250/300 |

70/84 |

65 |

40 |

7.5/7.5 |

2.5 |

295 |

|

LGB110 |

400/480 |

110/132 |

80 |

40 |

7.5/7.5 |

2.6 |

350 |

||

|

LGB160 |

576/690 |

160/192 |

100 |

65 |

15/15 |

2.8 |

480 |

||

|

LGB220 |

792/950 |

220/264 |

150 |

65 |

18.5/22 |

3 |

520 |

||

|

LGB220A |

792/950 |

220/264 |

150 |

80*80 |

18.5/22 |

3 |

800 |

||

|

LGB330 |

1188/1425 |

330/396 |

150 |

65 |

30/30 |

4 |

680 |

||

|

LGB450 |

1620/1944 |

450/540 |

200 |

80 |

45/45 |

6 |

950 |

||

|

LGB280 |

0.75/0.52 |

100/70 |

1008/1210 |

280/336 |

150 |

65 |

22/22 |

3.2 |

520 |

|

LGB300 |

1080/1290 |

300/360 |

150 |

65 |

22/22 |

4 |

520 |

||

|

LGB400 |

1440/1728 |

400/480 |

150 |

65 |

37/37 |

5 |

680 |

||

Note: The data in the table is the data of a single pump, and the exhaust diameter and quality of the equipment will change after the muffler is equipped.

Previous Page

Next Page

Previous Page

LGB-110 screw vacuum pump

Next Page

The pump cavity of the dry screw vacuum pump is equipped with a pair of synchronous reverse meshing rotating multi-stage spiral rotor, which divides the pump cavity into several non-connected cavities. In normal operation, with the meshing rotation of the two rotors, a suction cavity is generated and the volume increases continuously to suck in gas. When the volume reaches the maximum, the suction cavity turns into an intermediate cavity; the intermediate cavity moves to the right to transport the gas from the intake end to the exhaust end. When the intermediate cavity is connected with the exhaust port channel, the intermediate cavity turns into an exhaust cavity; the volume of the exhaust cavity decreases to discharge gas. When all the gas, the next intermediate chamber begins to be connected to the exhaust channel. This cycle to form a continuous pumping effect.

Dry screw vacuum pump can be divided into LG type equal pitch screw vacuum pump and LGB type variable pitch screw vacuum pump.

Dry screw vacuum pump is suitable for pumping all kinds of gases, and is suitable for vacuum brazing, vacuum sintering, vacuum annealing, vacuum coating, vacuum smelting, vacuum impregnation, vacuum drying, vacuum distillation, vacuum conveying, vacuum adsorption, vacuum packaging, vacuum casting and other processes. It is widely used in aerospace, electronics, metallurgy, medicine, chemical industry, semiconductor, coating, food packaging, freeze drying, casting and other industries.

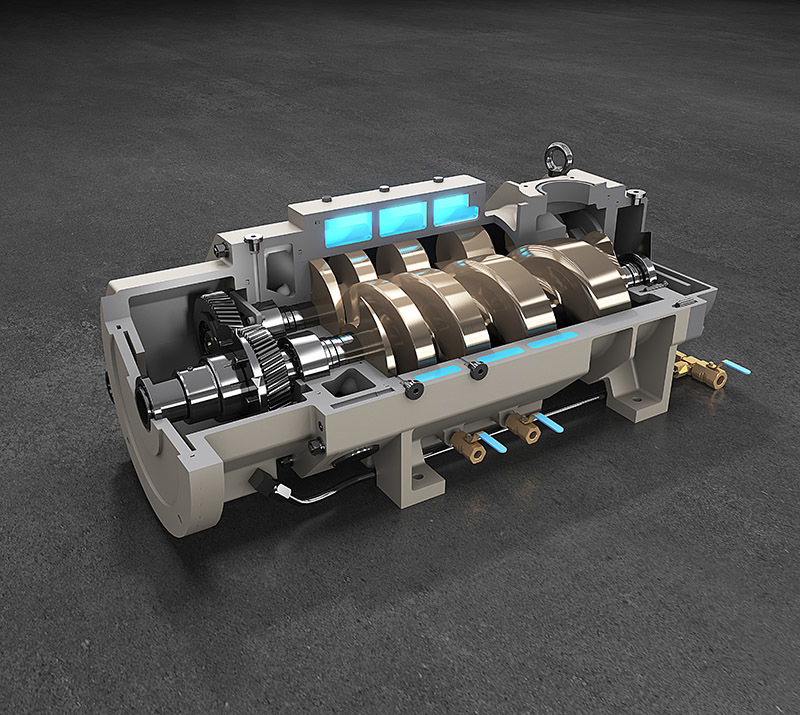

Schematic Construction Scheme:

Characteristic:

Compared with the equal pitch screw vacuum pump with the same pumping speed, the variable pitch screw vacuum pump has the following advantages:

-Lower power consumption and good energy saving effect;

-Low calorific value, low pump working temperature, low cooling water consumption;

-Low operating noise;

-Smaller size and smaller footprint.

Main performance parameters Performance Parameter:

|

Model Model |

ultimate pressure Ultimate Pressure (50/60Hz) |

pumping rate Pumping Speed (50/60Hz) |

Intake caliber Inlet Diam. ( mm ) |

Exhaust caliber Outlet Diam. ( mm ) |

with power Motor Power ( kW ) (50/60Hz) |

Cooling water quantity Cooling Water Consumption ( L/min ) |

Quality Weight (kg) |

||

|

Torr |

Pa |

m3/Hr |

L/S |

||||||

|

LGB70 |

0.015/ 0.0075 |

2/1 |

250/300 |

70/84 |

65 |

40 |

7.5/7.5 |

2.5 |

295 |

|

LGB110 |

400/480 |

110/132 |

80 |

40 |

7.5/7.5 |

2.6 |

350 |

||

|

LGB160 |

576/690 |

160/192 |

100 |

65 |

15/15 |

2.8 |

480 |

||

|

LGB220 |

792/950 |

220/264 |

150 |

65 |

18.5/22 |

3 |

520 |

||

|

LGB220A |

792/950 |

220/264 |

150 |

80*80 |

18.5/22 |

3 |

800 |

||

|

LGB330 |

1188/1425 |

330/396 |

150 |

65 |

30/30 |

4 |

680 |

||

|

LGB450 |

1620/1944 |

450/540 |

200 |

80 |

45/45 |

6 |

950 |

||

|

LGB280 |

0.75/0.52 |

100/70 |

1008/1210 |

280/336 |

150 |

65 |

22/22 |

3.2 |

520 |

|

LGB300 |

1080/1290 |

300/360 |

150 |

65 |

22/22 |

4 |

520 |

||

|

LGB400 |

1440/1728 |

400/480 |

150 |

65 |

37/37 |

5 |

680 |

||

Note: The data in the table is the data of a single pump, and the exhaust diameter and quality of the equipment will change after the muffler is equipped.

Previous Page

Next Page

Previous Page

LGB-110 screw vacuum pump

Next Page