LG-50 screw vacuum pump

Categorize:

LG Series

Summary:

Key words:

Vacuum equipment

LG-50 screw vacuum pump

The pump cavity of the dry screw vacuum pump is equipped with a pair of synchronous reverse meshing rotating multi-stage spiral rotor, which divides the pump cavity into several non-connected cavities. In normal operation, with the meshing rotation of the two rotors, a suction cavity is generated and the volume increases continuously to suck in gas. When the volume reaches the maximum, the suction cavity turns into an intermediate cavity; the intermediate cavity moves to the right to transport the gas from the intake end to the exhaust end. When the intermediate cavity is connected with the exhaust port channel, the intermediate cavity turns into an exhaust cavity; the volume of the exhaust cavity decreases to discharge gas. When all the gas, the next intermediate chamber begins to be connected to the exhaust channel. This cycle to form a continuous pumping effect.

Dry screw vacuum pump can be divided into LG type equal pitch screw vacuum pump and LGB type variable pitch screw vacuum pump.

Dry screw vacuum pump is suitable for pumping all kinds of gases, and is suitable for vacuum brazing, vacuum sintering, vacuum annealing, vacuum coating, vacuum smelting, vacuum impregnation, vacuum drying, vacuum distillation, vacuum conveying, vacuum adsorption, vacuum packaging, vacuum casting and other processes. It is widely used in aerospace, electronics, metallurgy, medicine, chemical industry, semiconductor, coating, food packaging, freeze drying, casting and other industries.

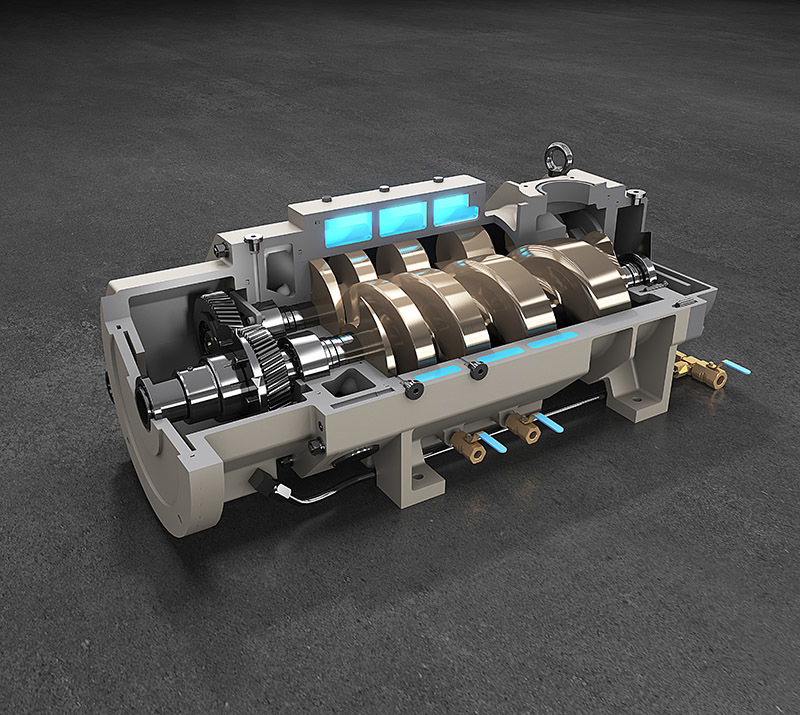

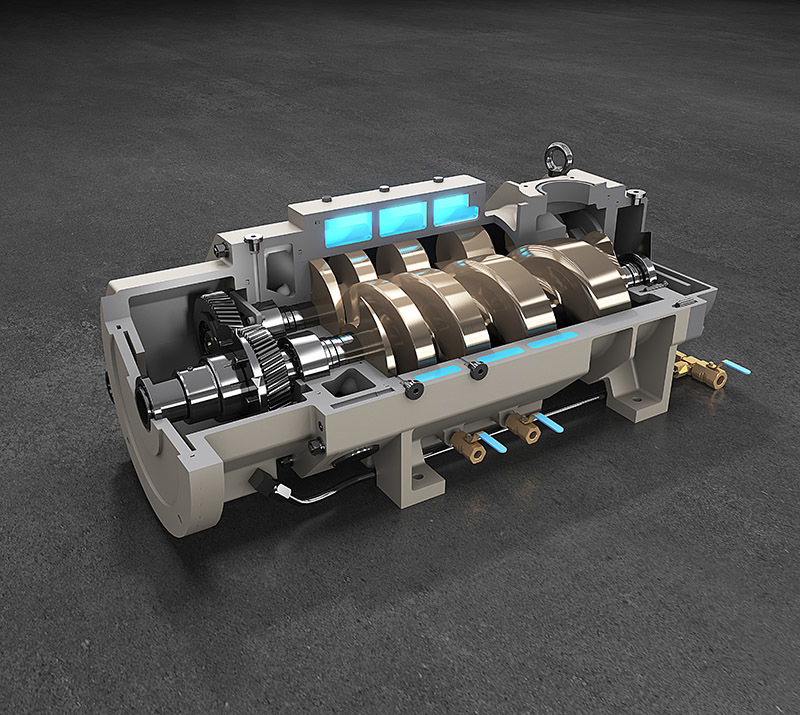

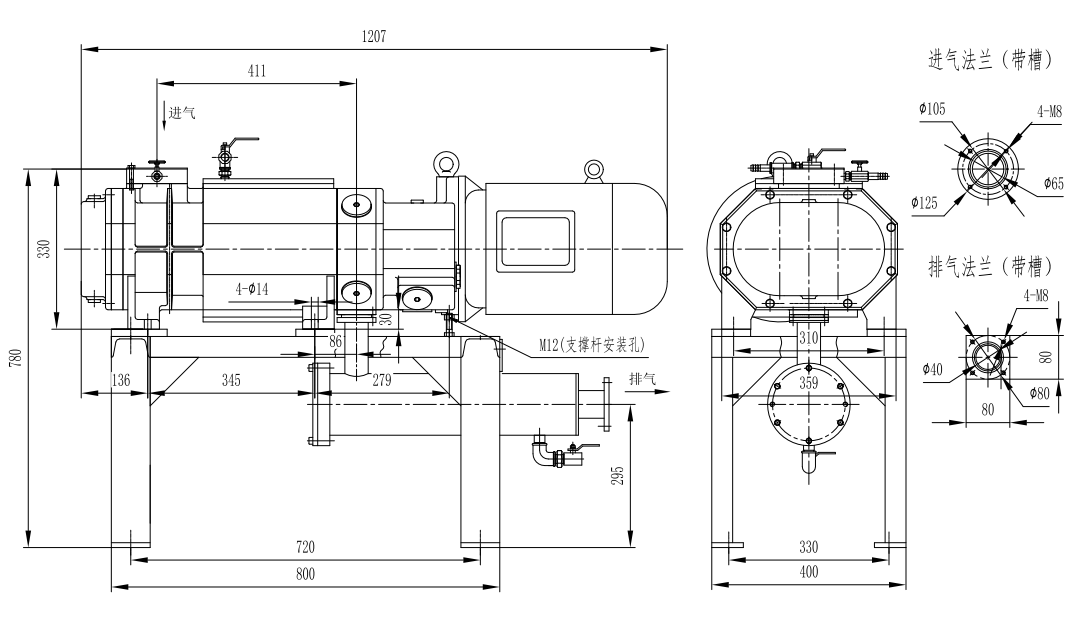

Schematic Construction Scheme:

Characteristic:

-There is no lubricating oil in the working cavity, and a clean vacuum can be obtained, which is conducive to improving product quality.

-There is no oil and gas pollution in the working cavity to be pumped gas, the process gas recovery rate is high, and the tail gas treatment is convenient; at the same time, the emission of oil, gas and oil fume is avoided, and the environmental pollution is small.

-There is no lubricating oil in the working cavity, which avoids the operation failure due to the emulsification and deterioration of lubricating oil, improves the stability of the system, and reduces the loss of lubricating oil in the pump.

-The pump has a wide range of applications. The working chamber of the pump and the surface of the spiral rotor are provided with anti-corrosion coating, which can adapt to harsh working conditions;

-The gap sealing structure is used between the moving parts in the pump cavity, which is not sensitive to a small amount of small particle dust, and the pump cavity is straight-through, without a middle partition structure, so the dust is not easy to deposit in the pump cavity; when the explosion-proof configuration is adopted, it can be used to pump out flammable and explosive gases.

-The pump can be used alone, or combined with Roots pump, molecular pump, etc. to form an oil-free vacuum unit, as the front pump of the unit. The single pump inlet pressure can work normally from 1Pa to atmospheric pressure, and the pumping efficiency is high, which can greatly simplify the vacuum pumping system.

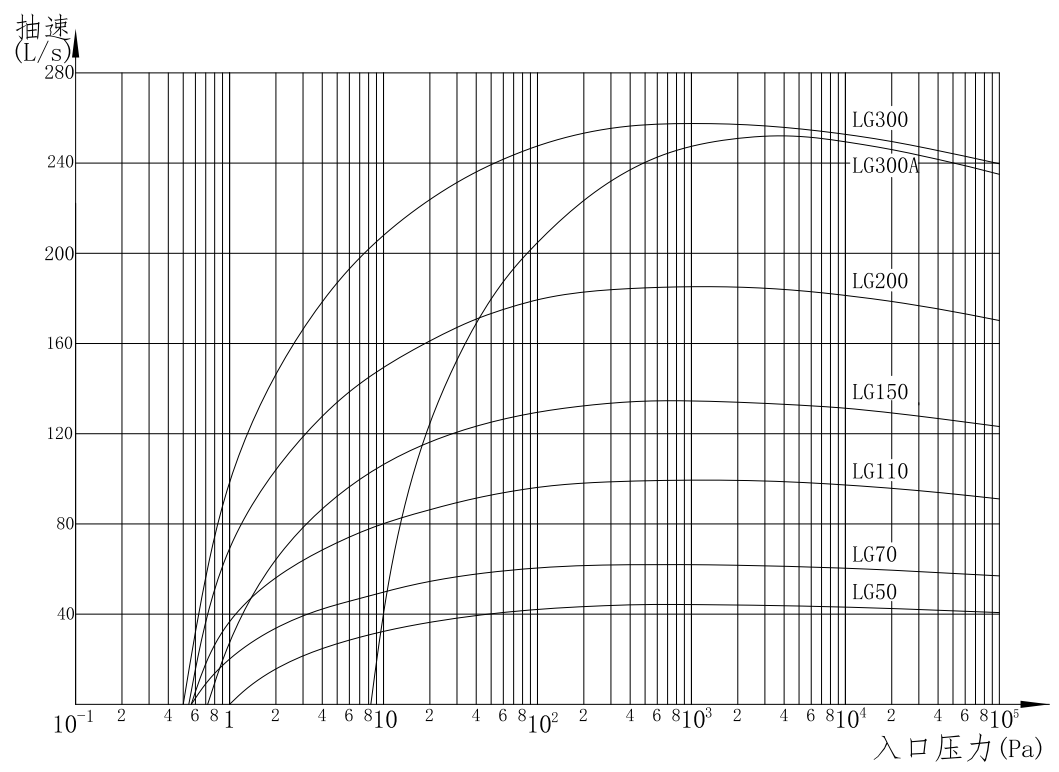

Main performance parameters Performance Parameter:

|

Model Model |

ultimate pressure Ultimate Pressure (50/60Hz) |

pumping rate Pumping Speed (50/60Hz) |

Intake caliber Inlet Diam. ( mm ) |

Exhaust caliber Outlet Diam. ( mm ) |

with power Motor Power ( kW ) (50/60Hz) |

Cooling water quantity Cooling Water Consumption ( L/min ) |

Quality Weight (kg) |

||

|

Torr |

Pa |

m3/Hr |

L/S |

||||||

|

LG50 |

0.015/ 0.0075 |

2/1 |

180/216 |

50/60 |

65 |

40 |

7.5/7.5 |

2.5 |

295 |

|

LG70 |

250/300 |

70/84 |

80 |

40 |

7.5/7.5 |

2.6 |

350 |

||

|

LG110 |

400/480 |

110/132 |

100 |

65 |

11/15 |

2.8 |

480 |

||

|

LG150 |

540/650 |

150/180 |

150 |

65 |

18.5/18.5 |

3 |

520 |

||

|

LG150A |

540/650 |

150/180 |

150 |

80*80 |

18.5/18.5 |

3 |

800 |

||

|

LG200 |

720/850 |

200/240 |

150 |

65 |

22/22 |

4 |

680 |

||

|

LG300 |

1080/1290 |

300/360 |

200 |

80 |

30/37 |

5.5 |

950 |

||

|

LG300A |

0.75/0.52 |

100/70 |

1080/1290 |

300/360 |

150 |

65 |

30/37 |

2.8 |

680 |

Note: The data in the table is the data of a single pump, and the exhaust diameter and quality of the equipment will change after the muffler is equipped.

Previous Page

Next Page

Previous Page

LG-70 screw vacuum pump

Next Page

The pump cavity of the dry screw vacuum pump is equipped with a pair of synchronous reverse meshing rotating multi-stage spiral rotor, which divides the pump cavity into several non-connected cavities. In normal operation, with the meshing rotation of the two rotors, a suction cavity is generated and the volume increases continuously to suck in gas. When the volume reaches the maximum, the suction cavity turns into an intermediate cavity; the intermediate cavity moves to the right to transport the gas from the intake end to the exhaust end. When the intermediate cavity is connected with the exhaust port channel, the intermediate cavity turns into an exhaust cavity; the volume of the exhaust cavity decreases to discharge gas. When all the gas, the next intermediate chamber begins to be connected to the exhaust channel. This cycle to form a continuous pumping effect.

Dry screw vacuum pump can be divided into LG type equal pitch screw vacuum pump and LGB type variable pitch screw vacuum pump.

Dry screw vacuum pump is suitable for pumping all kinds of gases, and is suitable for vacuum brazing, vacuum sintering, vacuum annealing, vacuum coating, vacuum smelting, vacuum impregnation, vacuum drying, vacuum distillation, vacuum conveying, vacuum adsorption, vacuum packaging, vacuum casting and other processes. It is widely used in aerospace, electronics, metallurgy, medicine, chemical industry, semiconductor, coating, food packaging, freeze drying, casting and other industries.

Schematic Construction Scheme:

Characteristic:

-There is no lubricating oil in the working cavity, and a clean vacuum can be obtained, which is conducive to improving product quality.

-There is no oil and gas pollution in the working cavity to be pumped gas, the process gas recovery rate is high, and the tail gas treatment is convenient; at the same time, the emission of oil, gas and oil fume is avoided, and the environmental pollution is small.

-There is no lubricating oil in the working cavity, which avoids the operation failure due to the emulsification and deterioration of lubricating oil, improves the stability of the system, and reduces the loss of lubricating oil in the pump.

-The pump has a wide range of applications. The working chamber of the pump and the surface of the spiral rotor are provided with anti-corrosion coating, which can adapt to harsh working conditions;

-The gap sealing structure is used between the moving parts in the pump cavity, which is not sensitive to a small amount of small particle dust, and the pump cavity is straight-through, without a middle partition structure, so the dust is not easy to deposit in the pump cavity; when the explosion-proof configuration is adopted, it can be used to pump out flammable and explosive gases.

-The pump can be used alone, or combined with Roots pump, molecular pump, etc. to form an oil-free vacuum unit, as the front pump of the unit. The single pump inlet pressure can work normally from 1Pa to atmospheric pressure, and the pumping efficiency is high, which can greatly simplify the vacuum pumping system.

Main performance parameters Performance Parameter:

|

Model Model |

ultimate pressure Ultimate Pressure (50/60Hz) |

pumping rate Pumping Speed (50/60Hz) |

Intake caliber Inlet Diam. ( mm ) |

Exhaust caliber Outlet Diam. ( mm ) |

with power Motor Power ( kW ) (50/60Hz) |

Cooling water quantity Cooling Water Consumption ( L/min ) |

Quality Weight (kg) |

||

|

Torr |

Pa |

m3/Hr |

L/S |

||||||

|

LG50 |

0.015/ 0.0075 |

2/1 |

180/216 |

50/60 |

65 |

40 |

7.5/7.5 |

2.5 |

295 |

|

LG70 |

250/300 |

70/84 |

80 |

40 |

7.5/7.5 |

2.6 |

350 |

||

|

LG110 |

400/480 |

110/132 |

100 |

65 |

11/15 |

2.8 |

480 |

||

|

LG150 |

540/650 |

150/180 |

150 |

65 |

18.5/18.5 |

3 |

520 |

||

|

LG150A |

540/650 |

150/180 |

150 |

80*80 |

18.5/18.5 |

3 |

800 |

||

|

LG200 |

720/850 |

200/240 |

150 |

65 |

22/22 |

4 |

680 |

||

|

LG300 |

1080/1290 |

300/360 |

200 |

80 |

30/37 |

5.5 |

950 |

||

|

LG300A |

0.75/0.52 |

100/70 |

1080/1290 |

300/360 |

150 |

65 |

30/37 |

2.8 |

680 |

Note: The data in the table is the data of a single pump, and the exhaust diameter and quality of the equipment will change after the muffler is equipped.

Previous Page

Next Page

Previous Page

LG-70 screw vacuum pump

Next Page