H-200GA slide valve vacuum pump

Categorize:

New generation slide valve pump series

Summary:

1. comparison of the old H-150 slide valve pump with the new H-200GA slide valve pump slide valve vacuum pump in China's production history of more than 60 years, has now formed the third generation of slide valve pump. We divide the development process of slide valve vacuum pump into three generations: the first generation of slide valve pump is the H-8 pump introduced to the Soviet Union in the 1950 s and the H-150 pump designed and produced in China in the 1960 s. Its structural arrangement is that the pump and the motor are on the same base. Such pumps have significant disadvantages such as large volume, not compact structure and large floor area. In order to overcome the above problems, it was later developed into a second-generation sliding valve pump with a motor placed on the pump tank.

Key words:

Vacuum equipment

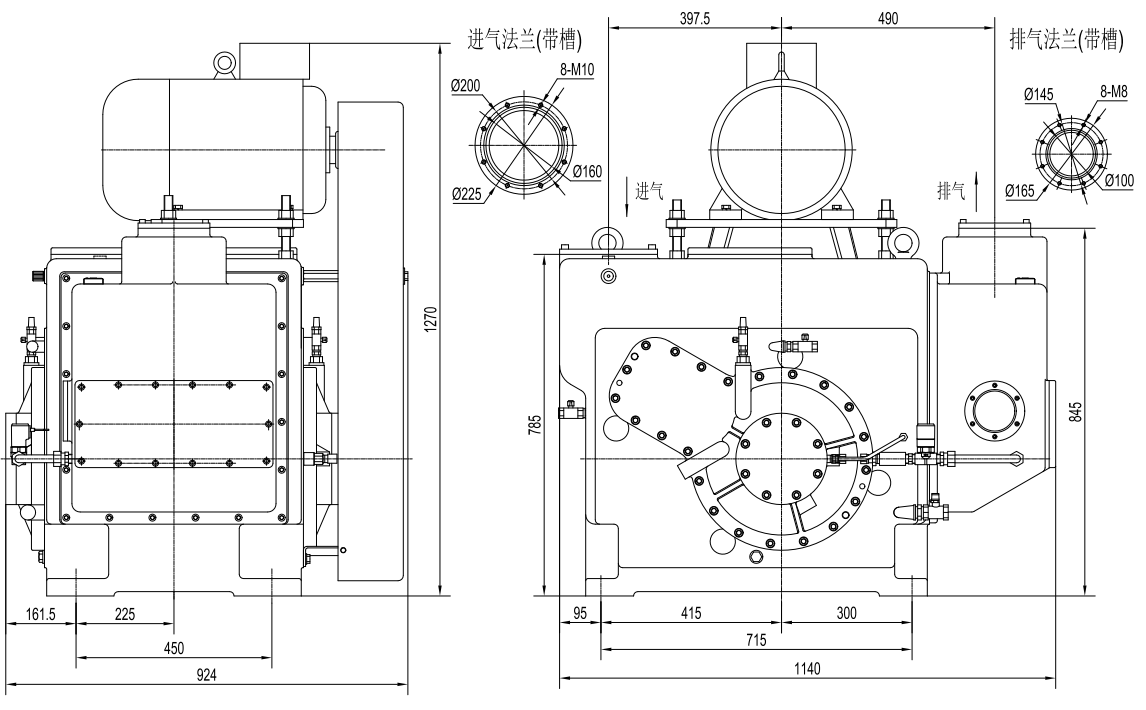

H-200GA slide valve vacuum pump

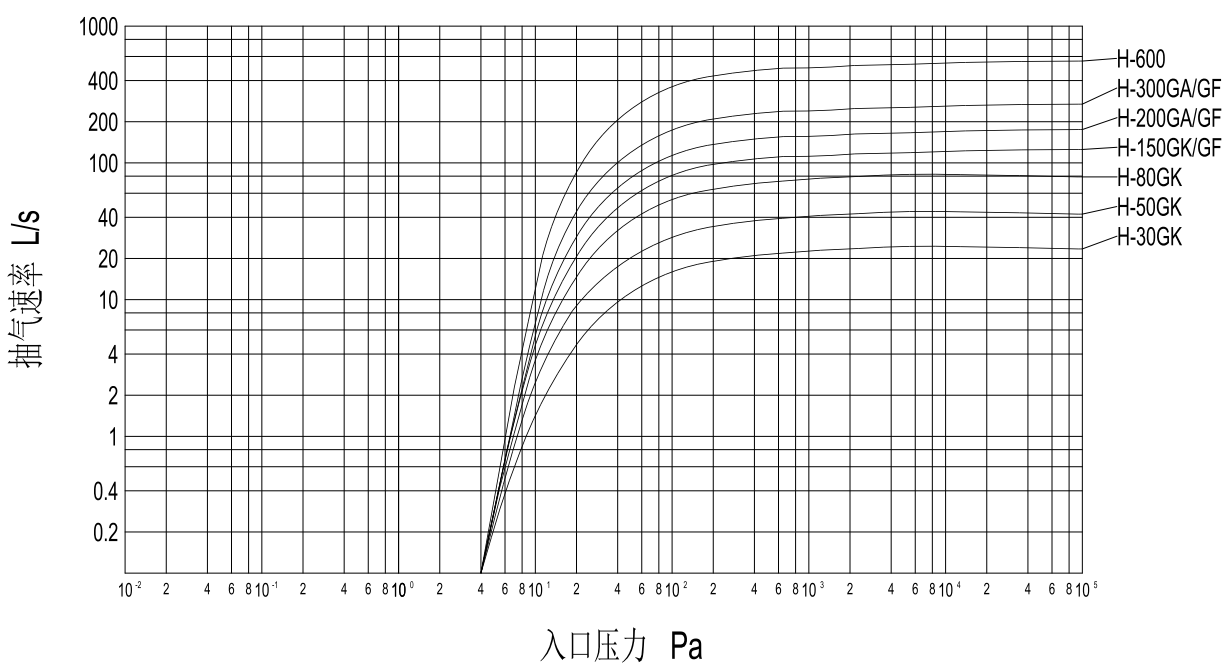

Slide valve vacuum pump has a single-stage H type and two-stage 2H type two types of structure.

Two-stage pump than a single-stage pump limit pressure is generally an order of magnitude lower (higher vacuum an order of magnitude).

This type of pump is suitable for pumping in addition to general gas. When a gas ballast valve is used, a gas containing a small amount of condensable vapor, such as water vapor, can also be pumped. When pumping gases that contain too much oxygen, are explosive, corrosive to ferrous metals, and chemically react with vacuum oil, additional devices should be added. This type of pump can be used alone, can also be used as oil diffusion pump, oil vapor jet pump, roots vacuum pump and other high vacuum pump before the pump. This type of pump is widely used in vacuum coating, vacuum heat treatment, vacuum sintering, vacuum metallurgy, vacuum drying, molecular distillation, electronics, solar energy, aviation, aerospace simulation test and other industries.

Characteristic

-Rotary parts are designed according to the point of view of dynamic balance counterweight, so that the pump vibration is small, smooth operation;

-As the moving parts of the pump take small eccentricity, the moment of inertia is small, and the power of the optional motor is also small. For example, H150G with the same pumping speed of 150L/s can be equipped with a 7.5kW motor in the coating industry, while H150 pump needs to be equipped with a 15kW motor;

-The main parts of the pump are optimized and designed with a high degree of generalization, such as slide valves, eccentric wheels, guide rails and pump covers, which can be used for H70G, 2H70G, H150G, 2H120G and other pumps;

-The joint surfaces of the pump body and the pump cover, the oil tank and the oil tank cover are all provided with sealing grooves, which are sealed by O-rings, which are reliable in sealing and convenient in assembly and disassembly, and the old sealing forms of paper pad or resin coating are abandoned;

-The oil and gas separators in the pump are all made of aluminum alloy (except H150), with beautiful appearance, and easy assembly and disassembly when repairing the exhaust valve;

-GA type pump for the bearing outward movement, separated from the pump chamber, separate oil supply, so as to avoid impurities or harmful gases into the bearing, prolong the service life of the bearing;

-GAP type pump for the bearing out and add oil supply pump, forced lubrication, especially suitable for the pump for a long time under the condition of high inlet pressure;

-According to user requirements, it can be equipped with an oil mist eliminator. When the pump works in any state, the exhaust port will eliminate oil fume and create a clean environment.

Main performance parameters Performance Parameter:

|

Model |

ultimate pressure |

pumping rate |

Intake caliber |

Exhaust caliber |

with power |

Cooling water quantity |

Weight |

|

|

Pa |

Tarr |

|||||||

|

H-200GA |

6.5 |

5 × 10-2 |

160 |

160 |

100 |

18.5 |

450 |

1155 |

Note 1: G in the table indicates the basic type, GA indicates that the bearing moves outward, GAP indicates that the bearing moves outward and the oil pump is forced to supply oil, and GB indicates that the small cylinder sliding rod is replaced by the guide rail assembly.

Note 2: The partial pressure in the table refers to the full pressure indication measured by a thermocouple vacuum gauge, etc.

Note 3: The matching power outside the brackets in the table is the standard configuration, and the matching power inside the brackets is the special configuration.

Note 4: Products marked with "*" in the table are produced according to the drawings of Korea Ucheng Vacuum Company.

Previous Page

Next Page

Previous Page

H-200GF slide valve vacuum pump

Next Page

Slide valve vacuum pump has a single-stage H type and two-stage 2H type two types of structure.

Two-stage pump than a single-stage pump limit pressure is generally an order of magnitude lower (higher vacuum an order of magnitude).

This type of pump is suitable for pumping in addition to general gas. When a gas ballast valve is used, a gas containing a small amount of condensable vapor, such as water vapor, can also be pumped. When pumping gases that contain too much oxygen, are explosive, corrosive to ferrous metals, and chemically react with vacuum oil, additional devices should be added. This type of pump can be used alone, can also be used as oil diffusion pump, oil vapor jet pump, roots vacuum pump and other high vacuum pump before the pump. This type of pump is widely used in vacuum coating, vacuum heat treatment, vacuum sintering, vacuum metallurgy, vacuum drying, molecular distillation, electronics, solar energy, aviation, aerospace simulation test and other industries.

Characteristic

-Rotary parts are designed according to the point of view of dynamic balance counterweight, so that the pump vibration is small, smooth operation;

-As the moving parts of the pump take small eccentricity, the moment of inertia is small, and the power of the optional motor is also small. For example, H150G with the same pumping speed of 150L/s can be equipped with a 7.5kW motor in the coating industry, while H150 pump needs to be equipped with a 15kW motor;

-The main parts of the pump are optimized and designed with a high degree of generalization, such as slide valves, eccentric wheels, guide rails and pump covers, which can be used for H70G, 2H70G, H150G, 2H120G and other pumps;

-The joint surfaces of the pump body and the pump cover, the oil tank and the oil tank cover are all provided with sealing grooves, which are sealed by O-rings, which are reliable in sealing and convenient in assembly and disassembly, and the old sealing forms of paper pad or resin coating are abandoned;

-The oil and gas separators in the pump are all made of aluminum alloy (except H150), with beautiful appearance, and easy assembly and disassembly when repairing the exhaust valve;

-GA type pump for the bearing outward movement, separated from the pump chamber, separate oil supply, so as to avoid impurities or harmful gases into the bearing, prolong the service life of the bearing;

-GAP type pump for the bearing out and add oil supply pump, forced lubrication, especially suitable for the pump for a long time under the condition of high inlet pressure;

-According to user requirements, it can be equipped with an oil mist eliminator. When the pump works in any state, the exhaust port will eliminate oil fume and create a clean environment.

Main performance parameters Performance Parameter:

|

Model |

ultimate pressure |

pumping rate |

Intake caliber |

Exhaust caliber |

with power |

Cooling water quantity |

Weight |

|

|

Pa |

Tarr |

|||||||

|

H-200GA |

6.5 |

5 × 10-2 |

160 |

160 |

100 |

18.5 |

450 |

1155 |

Note 1: G in the table indicates the basic type, GA indicates that the bearing moves outward, GAP indicates that the bearing moves outward and the oil pump is forced to supply oil, and GB indicates that the small cylinder sliding rod is replaced by the guide rail assembly.

Note 2: The partial pressure in the table refers to the full pressure indication measured by a thermocouple vacuum gauge, etc.

Note 3: The matching power outside the brackets in the table is the standard configuration, and the matching power inside the brackets is the special configuration.

Note 4: Products marked with "*" in the table are produced according to the drawings of Korea Ucheng Vacuum Company.

Previous Page

Next Page

Previous Page

H-200GF slide valve vacuum pump

Next Page